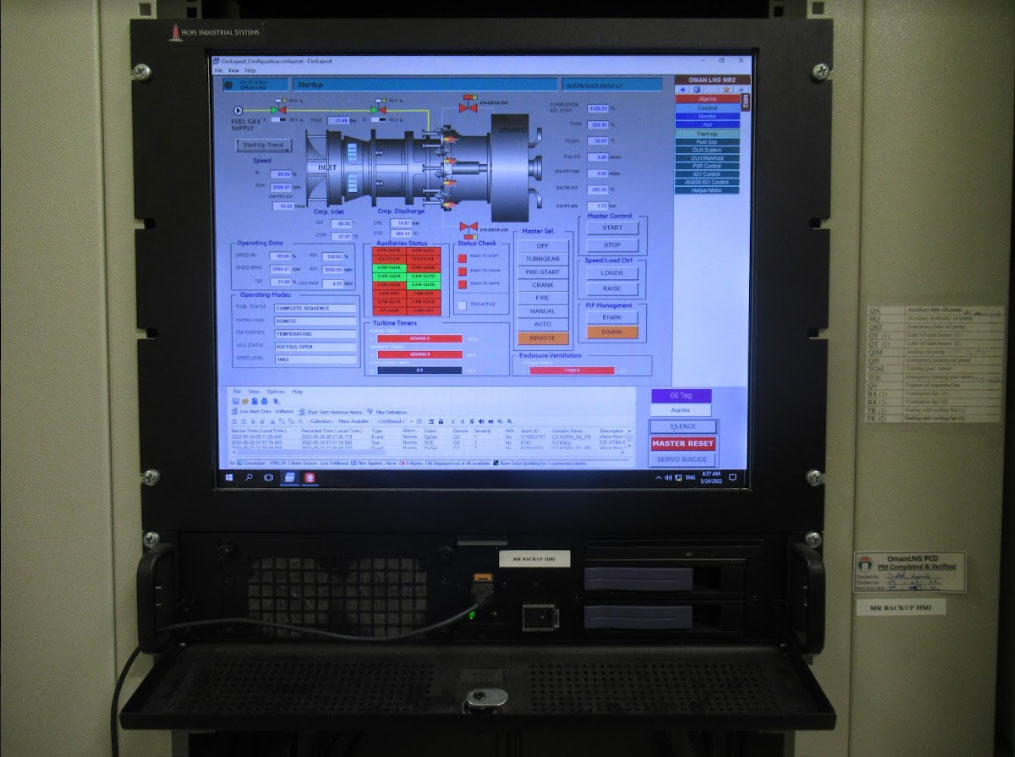

Speedtronic Mark V Gas Turbine Control Systems

The SPEEDTRONIC Mark V Gas Turbine Control System is the latest derivative in the highly successful SPEEDTRONIC series. Preceding systems were based on automated turbine control, protection and sequencing techniques dating back to the late 1940s, and have grown and developed with the available technology. Implementation of electronic turbine control, protection and sequencing originated with the Mark I system in 1968. The Mark V system is a digital implementation of the turbine automation techniques learned and refined in more than 40 years of successful experience, over 80% of which has been through the use of electronic control technology.

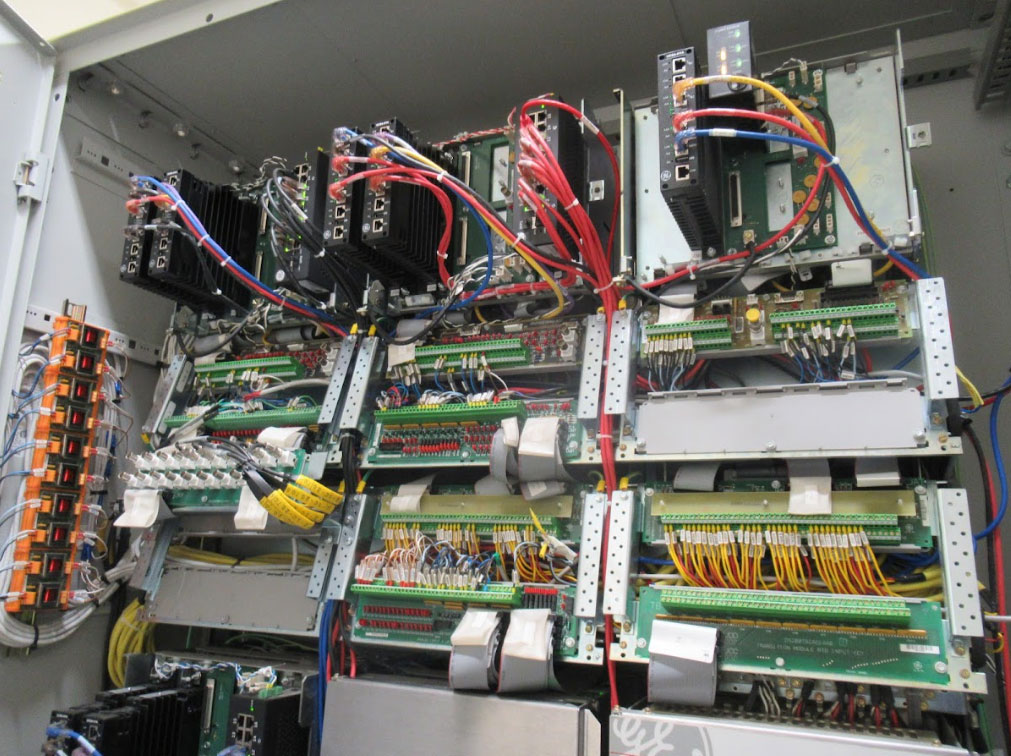

The SPEEDTRONIC Mark V Gas Turbine Control System employs current state-of-the-art technology, including triple-redundant 16-bit microprocessor controllers, two-out-of-three voting redundancy on critical control and protection parameters and Software-Implemented Fault Tolerance (SIFT). Critical control and protection sensors are triple redundant and voted by all three control processors. System output signals are voted at the contact level for critical solenoids, at the logic level for the remaining contact outputs and at three coil servo valves for analog control signals, thus maximizing both protective and running reliability.

Mark V

- Mark V is a turbine control system series developed by General Electric (GE). It is specifically designed to optimize the performance, ensure the safety, and enhance the efficiency of gas and steam turbines. It has been widely recognized as a reliable solution in the industry for many years.

Features

- Modular Design: Enables easy maintenance and expansion.

- Advanced Diagnostics: Quickly identifies issues to minimize downtime.

- High Security: Includes hardware and software-level protection mechanisms.

- Centralized Control: Offers remote monitoring and management of turbine operations.

- Application Flexibility: Compatible with various turbine models and adaptable to different energy generation scenarios.

Applications

- Power Plants: Essential for controlling gas and steam turbines used in electricity generation.

- Oil and Gas Industry: Ensures control and safety in turbine-based energy production systems.

- Industrial Processes: Used in large facilities for energy optimization and safety management.

- Renewable Energy: Can serve as a supporting control system in certain hybrid energy setups.

Operational Efficiency

Having the latest control system technologies allows your plant to keep your operation as efficiently as possible. Power plant operators can focus on what matters the most.

Minimize Unexpected Failures

Reliability and Availability are two main factors for power plants to succeed in the current power markets around the world. Avoid unexpected failures or even trips.