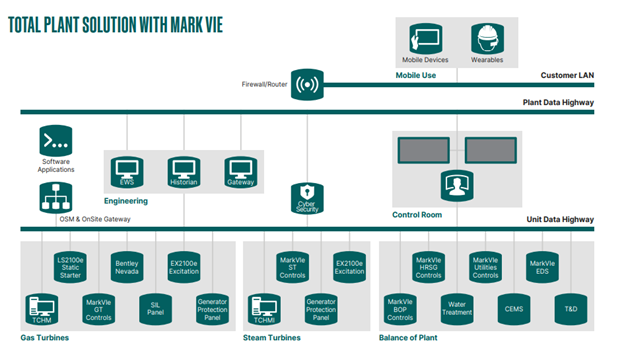

GE’s Mark VIe Distributed Control System (DCS) provides total plant control at a single level, combining the gas turbine, steam turbine, generator, boiler or HRSG, as well as balance-of plant equipment control in a single distributed architecture.

Built on our years of experience of providing superior turbine controls, GE’s Mark VIe control system is a flexible solution for today’s industry needs. The Mark VIe supports the most advanced turbine technology enabled by modern model-based control, providing a reliable, high-performance control system and the support to reduce plant lifecycle cost.

MARK VIE CONTROLLER

At the heart of the Mark VIe system is thecontroller that includes the main processor and triplicated Ethernet drivers to communicate with networked I/O, and additional Ethernet drivers for the control network. A set of two or three controllers can be used to providedual or TMR control.

Having the latest control system technologies allows your plant to keep your operation as efficiently as possible. Power plant operators can focus on what matters the most.

Reliability and Availability are two main factors for power plants to succeed in the current power markets around the world. Avoid unexpected failures or even trips.

No products in the cart.