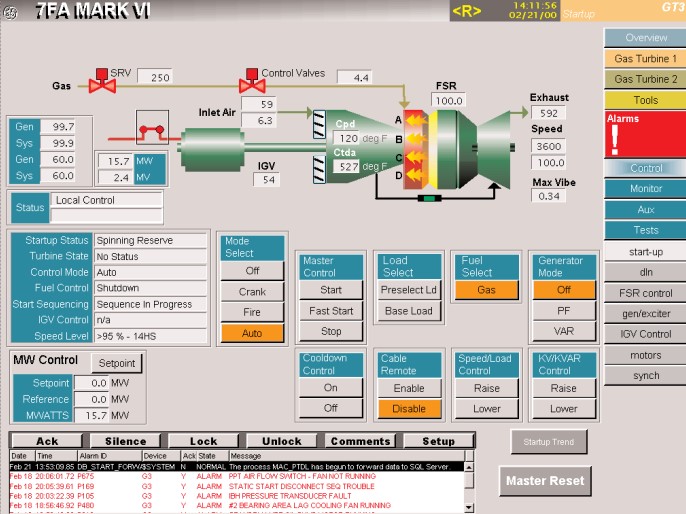

Speedtronic Mark VI Gas Turbine Control Systems

Mark VI turbine control is the current state-of-the-art control. It is designed as a complete integrated control, protection, and monitoring system for generator and mechanical drive applications of gas and steam turbines. It is also an ideal platform for integrating all power island and balance-of-plant controls.

Hardware and software are designed with close coordination between turbine design engineering and controls engineering to insure that your control system provides the optimum turbine performance and you receive a true “system” solution. With Mark VI, you receive the benefits of unmatched experience with an advanced turbine control platform.

Sourcing the Best of this Projects

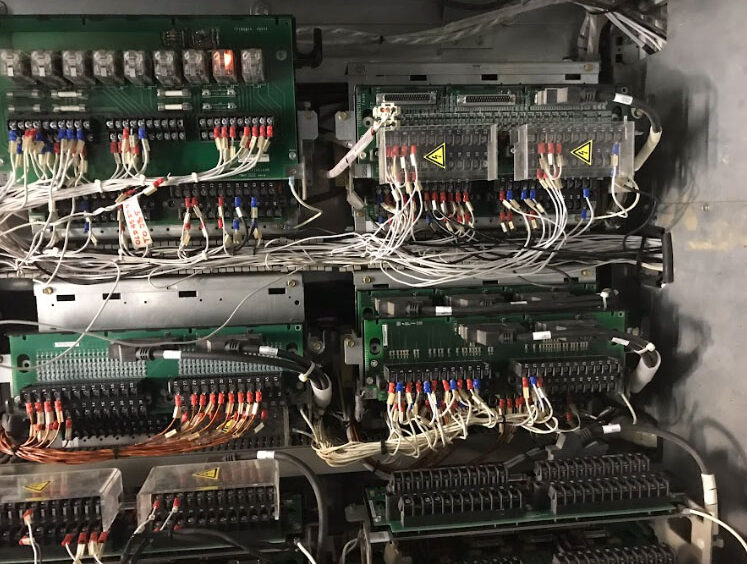

- I/O cards that are contained within its card rack

- I/O cards that may be contained in expansion I/O racks called Interface Modules

- I/O in backup <P> Protection Modules

- I/O in other Control Modules used in triple redundant control configurations

- The main processor card

Mark VI

- Mark VI is a turbine control system developed by General Electric (GE) for managing gas turbines, steam turbines, and other industrial applications. It serves as a robust solution for controlling and optimizing turbine performance, focusing on reliability and precision.

Features

- Integrated Control System: Combines control, protection, and monitoring in a single platform.

- Advanced Diagnostics: Provides real-time data and analytics to enhance performance and reduce downtime.

- Modular Design: Facilitates easy maintenance and scalability for various operational requirements.

- User-Friendly Interface: Equipped with an efficient Human-Machine Interface (HMI) for seamless operation and monitoring.

- Flexibility: Compatible with various turbine models and adaptable to different industry needs.

Applications

- Power Generation: Widely used in gas and steam turbines for electricity production in power plants.

- Oil and Gas Industry: Supports energy production and process optimization in critical operations.

- Industrial Facilities: Ensures the safe and efficient functioning of heavy machinery and production processes.

- Hybrid Energy Systems: Can be integrated into renewable energy setups to enhance control and efficiency.

Operational Efficiency

Having the latest control system technologies allows your plant to keep your operation as efficiently as possible. Power plant operators can focus on what matters the most.

Minimize Unexpected Failures

Reliability and Availability are two main factors for power plants to succeed in the current power markets around the world. Avoid unexpected failures or even trips.